Zhejiang Kangpurui Auto Parts Co., Ltd. is located in the Pinghu National Economic Development Zone in Zhejiang, within the 100-kilometer economic circle of Shanghai, Hangzhou and Ningbo.

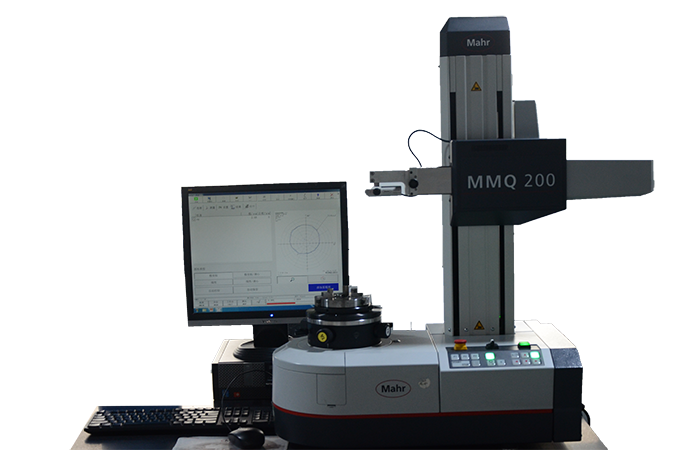

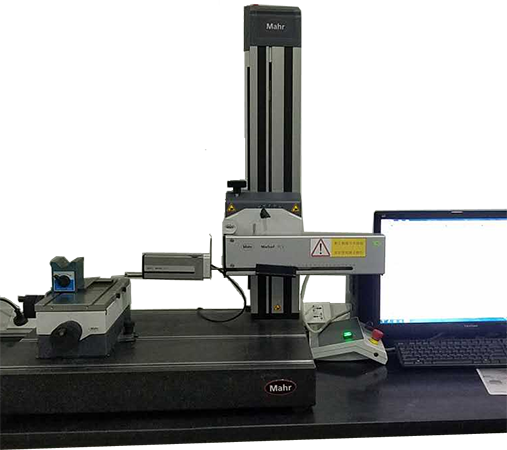

The company's main business is the production and sales of automotive transmission shaft standard parts. It has Germany Ipsen heat treatment equipment, Japan OKUMA automatic processing line, Japan NACHI broaching machine, Japan MURATEC double spindle lathe, Germany GEORG six window punching machine, Taiwan gold Feng punch, Ningxia Little Giant CNC, Jinshang precision three-pin professional machine tools and other production equipment; also has spectrometers, length gauges, roughness profilers, roundness meters, projectors, universal industrial microscopes and other testing equipment.

At present, the annual production capacity has reached 7 million pieces of three-pin shafts, 10 million pieces of inner star wheels, and 20 million pieces of cages (ball cages). The products are mainly supplied to Shanghai Natiefu Company for Shanghai Volkswagen, Shanghai GM, FAW-Volkswagen, Mercedes-Benz, BMW, Changan Ford, Shenlong Fukang and other well-known auto manufacturers, aiming to become China's largest manufacturer of transmission system standard parts, the cage is currently one of the largest domestic production capacity production enterprises.

With the continuous development of the company, the company's production equipment, testing equipment and other hardware are constantly upgraded. While expanding the production capacity, it has further promoted the automation transformation and upgrading of the company and ensured stable product quality. Relying on technological precipitation and continuous independent innovation, the company takes "zero defects" as the company's direction of hard work, continuously provides competitive products and services, and gradually grows into an excellent product and service provider for automotive chassis drive shaft standard parts.