Zhejiang Defu Precision Drive Manufacturing Co., Ltd. is located in the beautiful Jiangnan water town-Pinghu

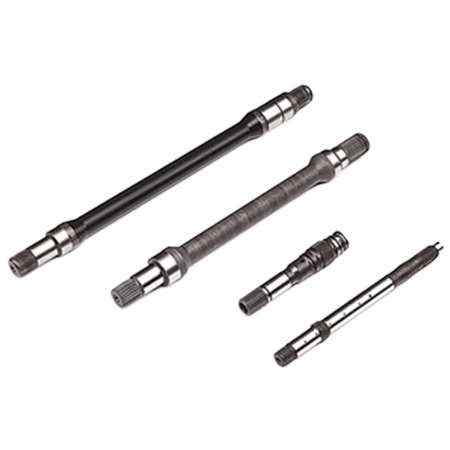

As an industry leader focusing on the manufacture of drive shaft forks, intermediate shafts, connecting shafts and drive shaft assemblies, Zhejiang Defu Precision Drive Manufacturing Co., Ltd., established in 2014, focuses on the cultivation of talents and maintains annual cooperation with universities. Has a solid knowledge of the R & D technical team.

At the same time, the company continues to invest huge sums of money to build advanced manufacturing production lines, using internationally renowned machining production equipment; adhere to quality first and excellent cost control as the guide, and adopt advanced management systems to ensure that customers are satisfied with products and services;